Categories

Products

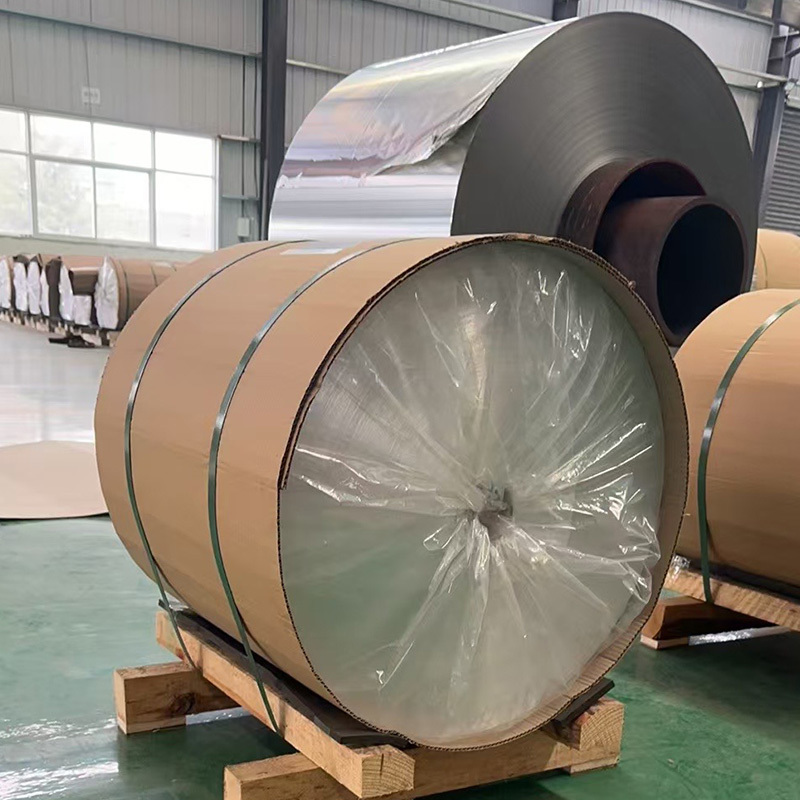

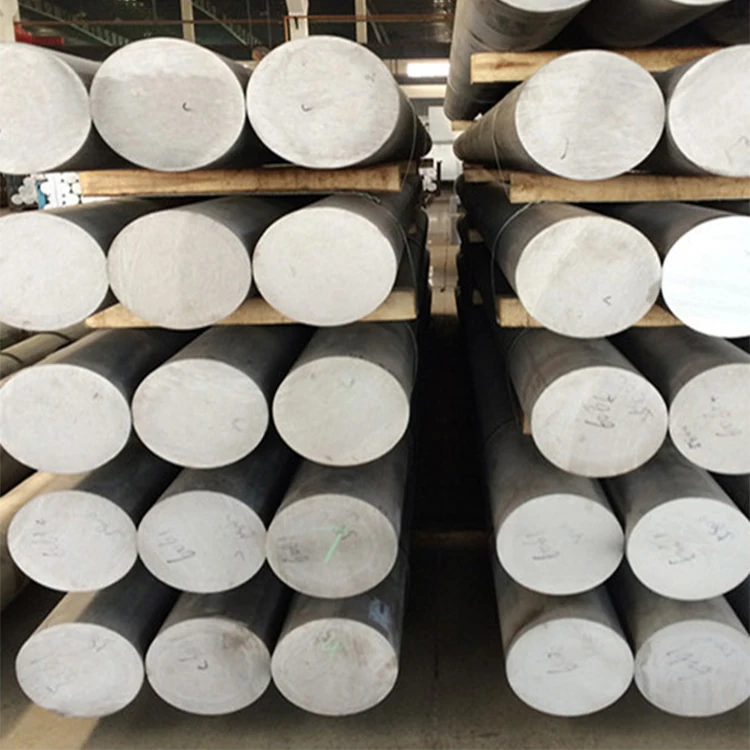

1050 aluminum alloy is formed by adding a small amount of copper in pure aluminum, which has excellent forming characteristics, high corrosion resistance, good weldability and electrical conductivity. It is widely used in products with low strength requirements, such as chemical instruments, sheet metal processing parts, deep drawing or spinning concave vessels, welding parts, heat exchangers, clock surface and disk surface, nameplate, kitchen utensils, decorations, reflective appliances, etc.

1050 aluminum alloy is formed by adding a small amount of copper in pure aluminum, which has excellent forming characteristics, high corrosion resistance, good weldability and electrical conductivity. It is widely used in products with low strength requirements, such as chemical instruments, sheet metal processing parts, deep drawing or spinning concave vessels, welding parts, heat exchangers, clock surface and disk surface, nameplate, kitchen utensils, decorations, reflective appliances, etc.

1050 aluminum alloy is formed by adding a small amount of copper in pure aluminum, which has excellent forming characteristics, high corrosion resistance, good weldability and electrical conductivity. It is widely used in products with low strength requirements, such as chemical instruments, sheet metal processing parts, deep drawing or spinning concave vessels, welding parts, heat exchangers, clock surface and disk surface, nameplate, kitchen utensils, decorations, reflective appliances, etc.

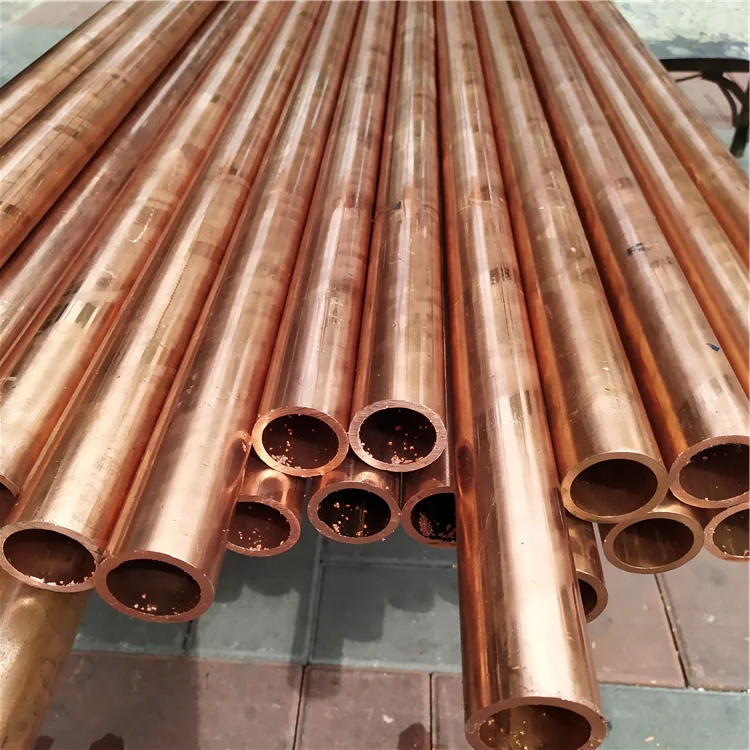

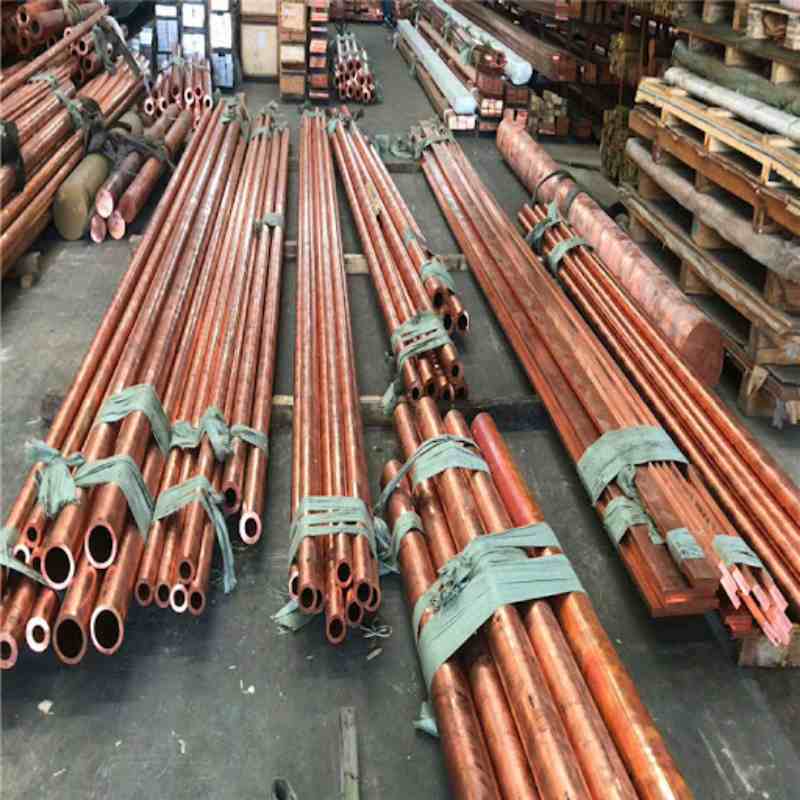

C11000/T2 is pure copper, also known as copper, copper has good electrical conductivity, thermal conductivity, corrosion resistance and processing performance, can be welded and brazed. Contains less impurities to reduce electrical conductivity, thermal conductivity, trace oxygen has little effect on electrical conductivity, thermal conductivity and processing properties, but it is easy to cause "hydrogen disease". It is not suitable for processing (annealing, welding, etc.) and use in a reducing atmosphere at high temperature (such as> 370 ℃).

High strength than pure copper (but in ordinary brass he is lower), good electrical and thermal conductivity, high corrosion resistance in the atmosphere and fresh water, good shaping, easy cold and hot pressure processing, easy forming, welding forging and tinning, no stress corrosion cracking tendency.

C12200/TP2 has good welding performance and cold bending performance. Generally, it has no "hydrogen disease" tendency. It can be processed and used in reducing atmosphere, but it is not suitable for processing and using in oxidizing atmosphere. It is mainly applied in pipe, and can also be supplied in plate, belt or bar and line. Used as gasoline or gas transmission pipe, drain pipe, condenser pipe, mine pipe, condenser, evaporator, heat exchanger, train parts.

C12000 welding performance and cold bending performance is good, generally no "hydrogen disease" tendency, can be processed in the reducing atmosphere, use, but not in the oxidizing atmosphere of processing, use, mainly to pipe applications, can also be plate, belt or bar, line supply. Used as gasoline or gas transmission pipe, drain pipe, condenser pipe, mine pipe, condenser, evaporator, heat exchanger, train parts.

C12000 welding performance and cold bending performance is good, generally no "hydrogen disease" tendency, can be processed in the reducing atmosphere, use, but not in the oxidizing atmosphere of processing, use, mainly to pipe applications, can also be plate, belt or bar, line supply. Used as gasoline or gas transmission pipe, drain pipe, condenser pipe, mine pipe, condenser, evaporator, heat exchanger, train parts.

C12000/TP1 has good welding performance and cold bending performance, generally has no "hydrogen disease" tendency, can be processed and used in reducing atmosphere, but should not be processed and used in oxidizing atmosphere, mainly for pipe application, but also for plate, belt or bar and line supply. Used as gasoline or gas transmission pipe, drain pipe, condenser pipe, mine pipe, condenser, evaporator, heat exchanger, train parts.

C10200/TU1 is a high-purity, oxygen-free, phosphorus-free deoxidized copper in vacuum without evaporating elements. It has high electrical and thermal conductivity, good welding performance and excellent welding performance attributes. It has excellent hot and cold forming properties, and has good compression resistance and corrosion resistance, especially in the atmosphere, due to the good adhesion of the oxide layer.

C10100/TU2C10100 oxygen-free copper cold and hot workability are excellent. Good forgeability. It can be used as a bus bar, waveguide, electron tube lead-in line and anode, vacuum seal, transistor components, speed control tube, microwave tube, rectifier.

C11000/T2 is pure copper, also known as copper, copper has good electrical conductivity, thermal conductivity, corrosion resistance and processing performance, can be welded and brazed. Contains less impurities to reduce electrical conductivity, thermal conductivity, trace oxygen has little effect on electrical conductivity, thermal conductivity and processing properties, but it is easy to cause "hydrogen disease". It is not suitable for processing (annealing, welding, etc.) and use in a reducing atmosphere at high temperature (such as> 370 ℃).

1050 aluminum alloy is formed by adding a small amount of copper in pure aluminum, which has excellent forming characteristics, high corrosion resistance, good weldability and electrical conductivity. It is widely used in products with low strength requirements, such as chemical instruments, sheet metal processing parts, deep drawing or spinning concave vessels, welding parts, heat exchangers, clock surface and disk surface, nameplate, kitchen utensils, decorations, reflective appliances, etc.

1050 aluminum alloy is formed by adding a small amount of copper in pure aluminum, which has excellent forming characteristics, high corrosion resistance, good weldability and electrical conductivity. It is widely used in products with low strength requirements, such as chemical instruments, sheet metal processing parts, deep drawing or spinning concave vessels, welding parts, heat exchangers, clock surface and disk surface, nameplate, kitchen utensils, decorations, reflective appliances, etc.

3A21 aluminum alloy is an ordinary industrial pure aluminum with an aluminum content of 99.0. It can not be strengthened by heat treatment; the strength is low, but it has good ductility, formability, weldability and corrosion resistance; after anodic oxidation, it can further improve its corrosion resistance and obtain a beautiful surface.

The 1100 aluminum alloy is an ordinary industrial pure aluminum with an aluminum content of 99.0. It can not be strengthened by heat treatment; the strength is low, but it has good ductility, formability, weldability and corrosion resistance; after anodic oxidation, it can further improve its corrosion resistance and obtain a beautiful surface.

254SMO is a stainless steel originally used in seawater and other aggressive chloride environments. This grade includes a very high-end austenitic stainless steel; consisting primarily of 17.5 to 18.5 percent nickel, 19.5 and 20.5 percent chromium, 6 to 6.5 percent molybdenum, and. 18 to. 22 percent nitrogen. In this "super austenitic" chemistry, these specific levels of Cr, Ni, Mo and N give the 31254 impact toughness to resist cracking, pitting and crevice corrosion, and almost twice the strength of 300 series stainless steel.

409 is a general purpose chromium, titanium stabilized ferritic stainless steel, its main application is automotive exhaust systems. It contains 11% chromium, which is the lowest amount to form a passive surface film, which makes stainless steel corrosion resistant. It combines good high temperature corrosion resistance, medium strength, good formability and overall cost. Compared with carbon steel, 409 has strong corrosion resistance and is used as a substitute for carbon steel in mildly challenging environments. In this environment, its high resistance to corrosion and high temperature oxidation has advantages. It is usually used in applications where appearance is a secondary quality to mechanical properties and corrosion resistance.